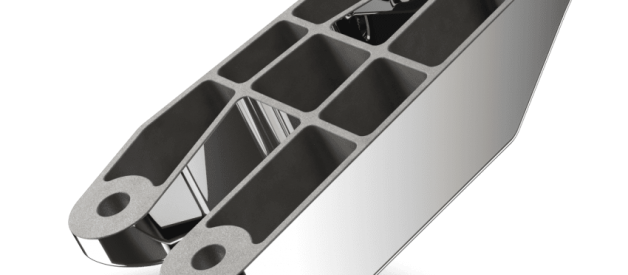

The process of melting metal is the main thing. There are two processes in this method one is heating the metal and another one is cooling the metal. The process involved two chambers hot chamber and a cool chamber. The big machine is involved in the process of hot chamber die casting. hot chamber dies casting involving the metals with the low melting point in case if we use metals with a high melting point can cause gooseneck and nozzle melt. The process is highly performed with the alloys like zinc and magnesium. The EKO industries do the best quality of die casting. The EKO has the world level customer do works depend on their lifestyle. The EKO industries with the high-quality precision-engineered products on earth. EKO uses less amount of manpower during the process uses a large amount of machinery for perfection.

EKO is the best companies in the process of custom aluminium die casting with a large number of advanced machines. Metals with low melting can easily melt by EKO if u have cold melting metals it can also do with a cold chamber. EKO is one of the best companies to work with the demands of the customer. The company uses a large amount of capital cost in the process of hot chamber die casting. The hot chamber built with a furnace to melt the metal. The melted metal is sent to the die cavity and passes through the gooseneck. The cooling chamber has different methods and processes. The above two processes can be performed by EKO industries. The EKO industries are one of the fastest-growing company in this field. There are several processes in the melting and casting of alloys or metals. Injection mechanism is the first step in the hot chamber machine. EKO industries use this complex structure to produce highly precise and accurately detailed parts.